The Duty of Welding Shirts in Offering Important Safety Features While Preserving Style and Performance for Welding Professionals

Welding t shirts serve a dual function, providing vital security features while enabling professionals to maintain a feeling of design in their job environment. Created from flame-resistant materials and developed with protective elements, these garments successfully protect against dangers fundamental in welding.

Importance of Safety in Welding

Why is safety critical in the welding industry? The welding industry includes a myriad of hazards that present substantial risks to employees' health and wellness. From direct exposure to severe heat and molten steel to the threats of electrical shock and toxic fumes, welders run in settings where the potential for injury and health problem is ever-present. Guaranteeing security is not merely a regulatory need; it is important for the health of workers and the sustainability of operations.

Welders deal with threats such as burns, eye injuries from ultraviolet radiation, and respiratory system problems as a result of breathing in dangerous fumes. The consequences of inadequate precaution can cause serious injuries, pricey clinical costs, and lowered labor force productivity. Applying thorough safety and security procedures, consisting of making use of suitable personal safety equipment (PPE), is important in mitigating these threats.

Moreover, cultivating a culture of safety within a welding procedure advertises understanding and alertness among employees. Training programs, normal security audits, and the stipulation of high-quality security equipment contribute to decreasing hazards. Ultimately, prioritizing security not only shields specific welders but additionally improves the general performance and online reputation of welding services.

Trick Security Attributes of Welding Shirts

When choosing welding t-shirts, it is important to look for specific safety attributes that properly protect against the integral dangers of the work. The main product needs to be flame-resistant; materials such as cotton treated with flame-retardant chemicals or specialized synthetic materials are optimal. These products aid stop ignition and decrease the danger of burns.

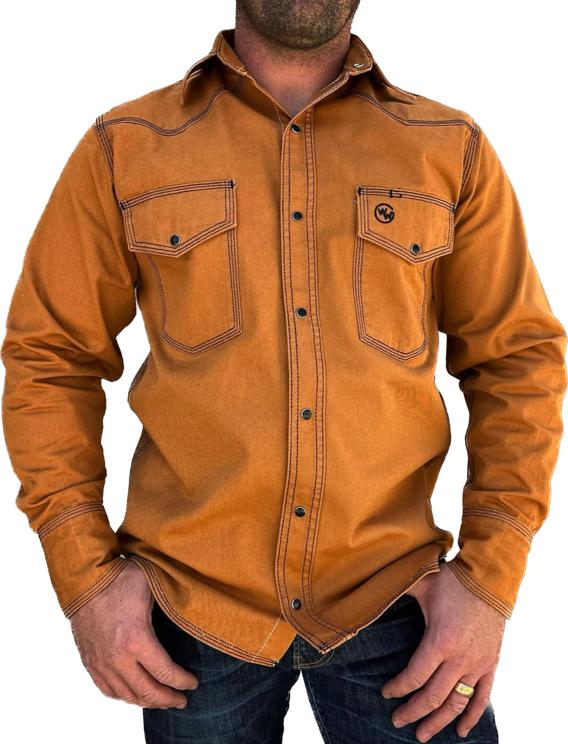

An additional essential attribute is the tee shirt's design, which should offer a tight fit without being limiting. Loose textile can catch on equipment or come right into contact with warm surface areas, increasing the risk of mishaps (Best Welding Shirts). Reinforced seams and durable stitching are also vital, as they improve durability and make sure that the shirt endures the roughness of welding

Furthermore, welding t shirts ought to consist of protective components such as high collars and long sleeves to shield the skin from sparks and UV radiation. Pockets designed to maintain devices and personal things protect can enhance functionality while limiting exposure to threats. Ultimately, take into consideration tee shirts with moisture-wicking properties, which assist maintain comfort throughout intense job, as excessive warmth can lead to lowered concentration and increased danger of mishaps. Picking a welding shirt with these vital functions is crucial for advertising safety and security on the task.

Stylish Layouts for Welders

Just how can welders express their individual design while sticking to safety and security standards? Welding shirts have actually progressed significantly, supplying a blend of safety features and aesthetic charm. Welders can now select from a range of shades, patterns, and creates that show their individuality while guaranteeing compliance with security policies.

In enhancement to aesthetic appeals, lots of producers are including trendy aspects such as contrasting sewing, elegant fits, and resilient yet classy fabrics. Such layouts not just enhance the visual charm however likewise maintain the capability required for a requiring work setting.

Moreover, the increase of sustainable fashion has actually affected welding clothing, with environmentally friendly products gaining popularity. This pattern enables welders to make diligent selections without giving up style. Ultimately, welding t-shirts now satisfy the requirement Learn More for both safety and security and individual expression, ensuring that professionals can work confidently and smartly in their requiring duties.

Products Utilized in Welding Shirts

The option of materials utilized in welding t shirts is critical for ensuring both safety and convenience in the workplace. Typically, welding t-shirts are crafted from long lasting textiles that can hold up against the severe problems of welding settings. Cotton is a preferred choice due to its breathability and comfort; however, it must be dealt with to have a greater flame resistance.

One more commonly used material is flame-resistant (FR) polyester, which combines resilience with outstanding warmth security. This synthetic fiber is lightweight yet provides exceptional resistance to flames and sparks, making it perfect for heavy-duty jobs. In addition, combined materials integrating both cotton and polyester can use boosted performance, balancing convenience with security.

Some welding t-shirts incorporate advanced products, such as Kevlar, recognized for its exceptional toughness and heat resistance, even more enhancing security attributes. Additionally, moisture-wicking residential properties in specific textiles help to keep welders completely dry and comfortable, minimizing the risk of warm stress and anxiety during lengthy hours of work.

Ultimately, the selection of appropriate products not just plays a significant role in securing welders from possible dangers but additionally adds to their general comfort, enabling them to do their tasks properly and efficiently.

Balancing Performance and Aesthetics

Welding t-shirts serve a double function, supplying crucial protection while also reflecting the wearer's personal style. In an industry where safety is critical, the style of welding clothing need to focus on capability without sacrificing aesthetic appeal. This balance is crucial, as professionals frequently look for garments that not just shield versus sparks, warmth, and hazardous products yet additionally allow for personal expression and convenience.

To accomplish this stability, producers are increasingly utilizing innovative products that supply both durability and visual appeal. As an example, tee shirts made from flame-resistant materials can be created in different colors and patterns, allowing welders to share their uniqueness while adhering to safety standards - Best Welding Shirts. Additionally, thoughtful style attributes such as enhanced seams, pockets for tools, and moisture-wicking properties enhance functionality without endangering design

Additionally, the incorporation of modern-day tailoring techniques makes certain a lovely fit, which is essential for convenience during lengthy hours of job. Eventually, welding shirts that efficiently balance performance and looks empower experts to execute their jobs efficiently while feeling great and elegant in their look. This harmonious combination of safety and fashion is necessary in fostering a positive job environment for go to my blog welding experts.

Verdict

In verdict, welding tee shirts are essential for making certain the safety and security of welding specialists while concurrently supplying fashionable and functional alternatives. Inevitably, welding tee shirts exhibit the effective equilibrium in between safety capability this hyperlink and aesthetic appeal, reinforcing the significance of both in the welding occupation.